Condition:

New

Batch Time(times/hour):

8 Times/hour

Total Capacity(L):

5 L

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

Ordinary Product

Warranty Of Core Components:

2 Years

Core Components:

PLC, Engine, Motor, Rotor

Model Number:

ZL-3011

Voltage:

380

Dimension(L*W*H):

1.6*0.9*1.9m

Year:

CUSTOM

Warranty:

2 Years

Key Selling Points:

High Productivity

Power (kW):

3.7 KW

Weight (KG):

800 KG

Showroom Location:

None

Applicable Industries:

Manufacturing Plant, Rubber And Plastic Industry

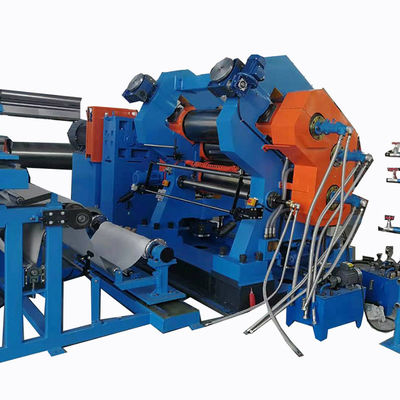

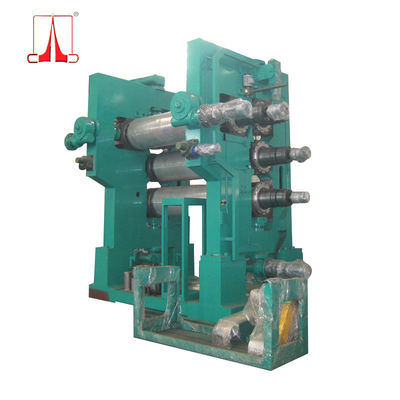

Name:

Kneader Extruder, Rubber Kneader Machine, Banbury Internal Mixer

Application:

Rubber / Plastic / Silicone

Mixing Capacity:

0.5~20L/Can Be Customized

Heating Mode:

Electricity Heating;

Cooling Mode:

Air Cooling ; Water Cooling

Turning Angle:

0-180 Degree

Air Compressor:

Option

Dust Collection:

Option

Display:

PLC Touch Screen

Weight:

800KG

After-sales Service Provided:

Free Spare Parts, Field Maintenance And Repair Service, Video Technical Support, Field Installation, Commissioning And Training, Online Support

Local Service Location:

None

After Warranty Service:

Video Technical Support, Online Support

Certification:

CE/ISO

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!