Application:

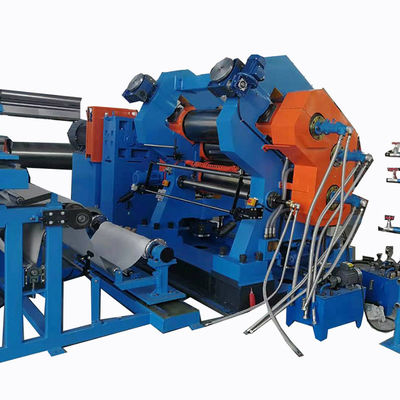

Mat

Plastic Processed:

PVC

Condition:

New

Screw Design:

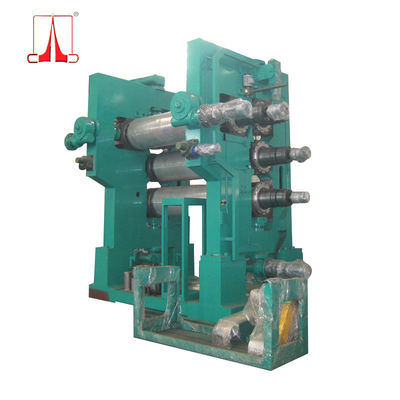

Double-screw

Twin Screw Type:

Conicial Twin Screw

Screw Material:

38CrMoAL

Screw Diameter (mm):

80/156

Screw L/D Ratio:

22:1

Screw Speed (rpm):

35 Rpm

Showroom Location:

Egypt, Turkey, Pakistan, Morocco, UAE, Algeria, South Africa

Voltage:

380V 50HZ 3Phase(Customized)

Dimension(L*W*H):

40mx3mx3m

Power (kW):

200

Weight:

8-20T

Warranty:

More Than 5 Years

Key Selling Points:

High Technology

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction Works , Energy & Mining, Food & Bevera

Marketing Type:

New Product 2020

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty Of Core Components:

More Than 5 Years

Core Components:

Bearing, Motor, Pump, Pressure Vessel, Engine, Gearbox, Screw

After-sales Service Provided:

Engineers Available To Service Machinery Overseas, Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support

Product:

PVC Floor Mat

Inverter:

ABB Or Delta Brand

Automatic Grade:

Automatic

Power(W):

200kw

Mat Width:

1200-2000mm

After Warranty Service:

Video Technical Support, No Service, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

Egypt, United States, Philippines, Pakistan, None

Output (kg/h):

200 - 500 Kg/h

Certification:

CE ISO

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!